Beside environmental aspects, high oil prices increase the necessity of the use of renewable energy sources. Biomass is a renewable energy source, which allows a sustainable utilization for several reasons. Its carbon dioxide neutrality and high availability make economic usage of this source possible. Rather for generating heat and power, a more sophisticated way of using biomass is transforming it into a secondary energy source by liquefaction and gasification. The product of the gasification process – is a medium calorific product gas, which is nearly free from nitrogen and has a H2 : CO ration favorable for synthesis processes. Therefore, the product gas can be converted into a Synthetic Natural Gas (Bio-SNG). The compressed Bio-SNG can be stored in a fuelling station to supply energy to CNG vehicles. It can also be injected to the natural gas grid.

Process

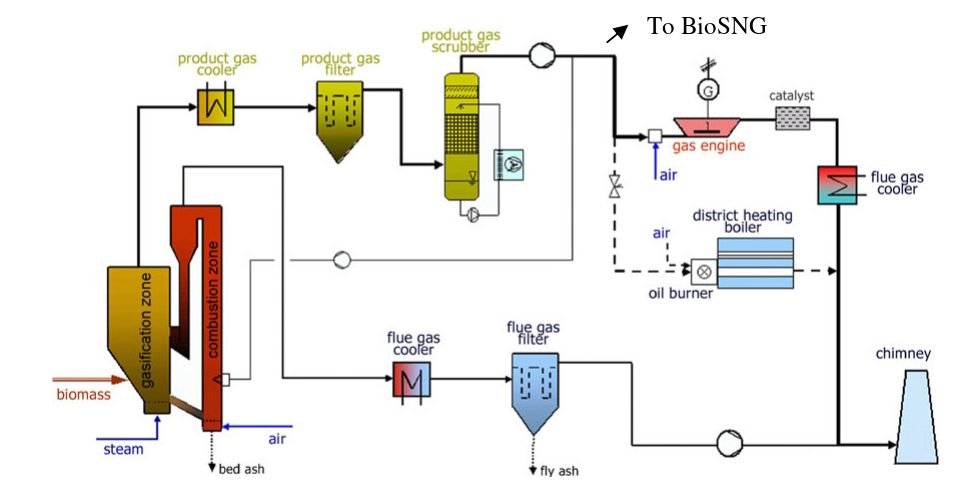

For the production of Bio-SNG from biomass, syngas from DFB gasifier is very effective as it is high in hydrogen (apprx. 40 vol.% (dry)), low in nitrogen (< 2 vol.% (dry)) and contains a rather high amount of methane (apprx. 9 vol.% (dry)).

The product gas generated by the gasifier is cleaned from dust (ash) and tar after sensible heat recovery. This is carried out by a bag house filter and a subsequent scrubber using rape seed methyl ester (RME) as a solvent for the tars.

In the Bio-SNG production, additional cleaning is done. Here, several scrubbing stages are installed to avoid the transport of substances with the product gas that would damage the methanation catalyst.

Methanation reactions :

| CO + 3 H2 <–> CH4 + H2O | CO methanation reaction | Exothermal |

| CO2 + 4 H2 <–> CH4 + 2H2O | CO2 methanation reaction | Exothermal |

| CO + H2O <–> H2 + CO2 | Water-gas shift reaction | Exothermal |

| C2H4 + 2H2O <–> 2CO + 4H2 | Reforming reaction | Endothermal |

The conditioned product gas enters the methanation reactor where the CH4 content is increased essentially. Then the raw SNG (the gas exiting the methanation reactor) passes several purification steps to increase the methane content up to a ratio to meet the regulations for feeding into the natural gas grid or for fuelling station.

The required raw SNG upgrading steps consists of ammonia scrubbing (sulphuric acid), CO2 scrubbing (using amine), drying (using condensation and glycol scrubbing) as well as (excess) hydrogen separation and recirculation using membrane technology. Enough cares have been taken to fulfill health and safety requirements.